The New Way of Protecting the Auto Body

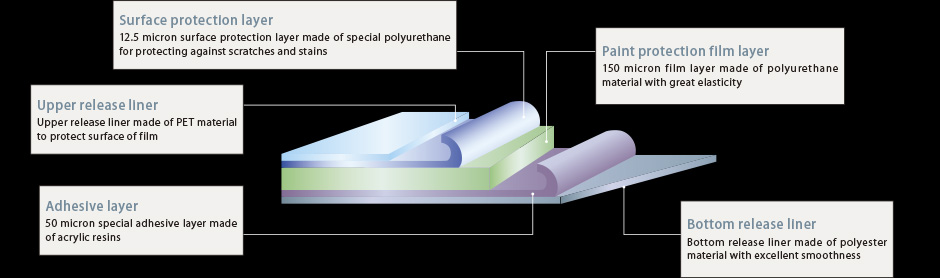

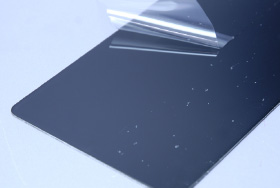

The traditional way for car owners to maintain the good appearance of their cars was to apply an auto body coating on the car. However, even though coatings may protect the car from small scratches and contaminants, it cannot completely cover huge scratches and dents. The PPF conforms to complex shapes and protects the car from scratches and dents with its high protective force and stretch properties. Moreover, the appearance of the car will not be changed due to its high transparency and gloss.